G MAX NW SERIES

new handheld

welding & cleaning system

NWorld new G MAX NW SERIES is a new line of Laser generators, designed and made to increase productivity and reduce costs, with high performance and unmatched aesthetic results compared to any other welding system.

It features a revolutionary fiber laser system that allows for the welding and cleaning of different metallic materials, now also equipped for Industry 4.0. Our innovative laser line is the ideal choice to embrace the future, a fundamental complement to traditional systems.

High welding

efficiency

1. 5 to 10 times faster than traditional TIG welding.

2. Low thermal distortion and the absence of spatter dramatically reduce the need for post- weld cleaning and the use of chemical reagents.

Energy savings

and efficiency

1. Cost savings of 70-80% in practical production thanks to high production speed.

2. Reduced energy costs due to a maximum absorption capacity of 6 kW at 220 Volts

Ease of use

and rapid training:

1. It only takes 4 hours to learn how to use our lasers and apply them in production.

2. No specific skills are required; anyone can quickly learn how to use this equipment..

Fast and punctual

customer service.

1. TUV Rheinland certification

2. Nworld customer service

3. European standard components

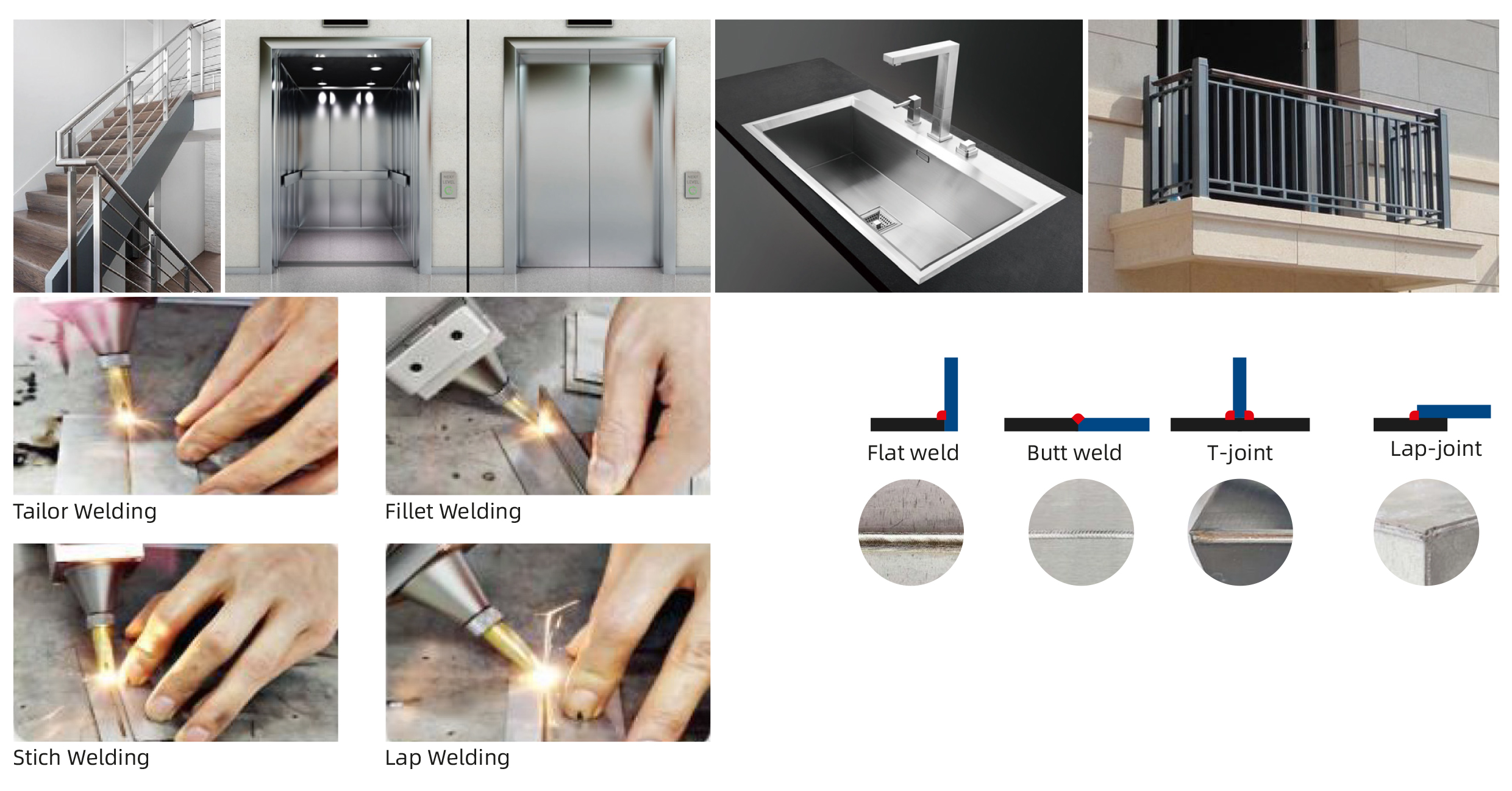

Applications

The most versatile technology for your work

Laser welding is widely used in the metalworking industry and is a highly effective method in automated and robotic manufacturing. It is currently the best and most durable welding solution for welding stainless steel, carbon steel, galvanized sheet metal, aluminum, copper, alloys, and other metals.

![]()

Multi-point welding mode

![]()

Separate wirefeeder

![]()

Touch screen digital display

![]()

built-in cooling system

![]()

Ergonomic design

![]()

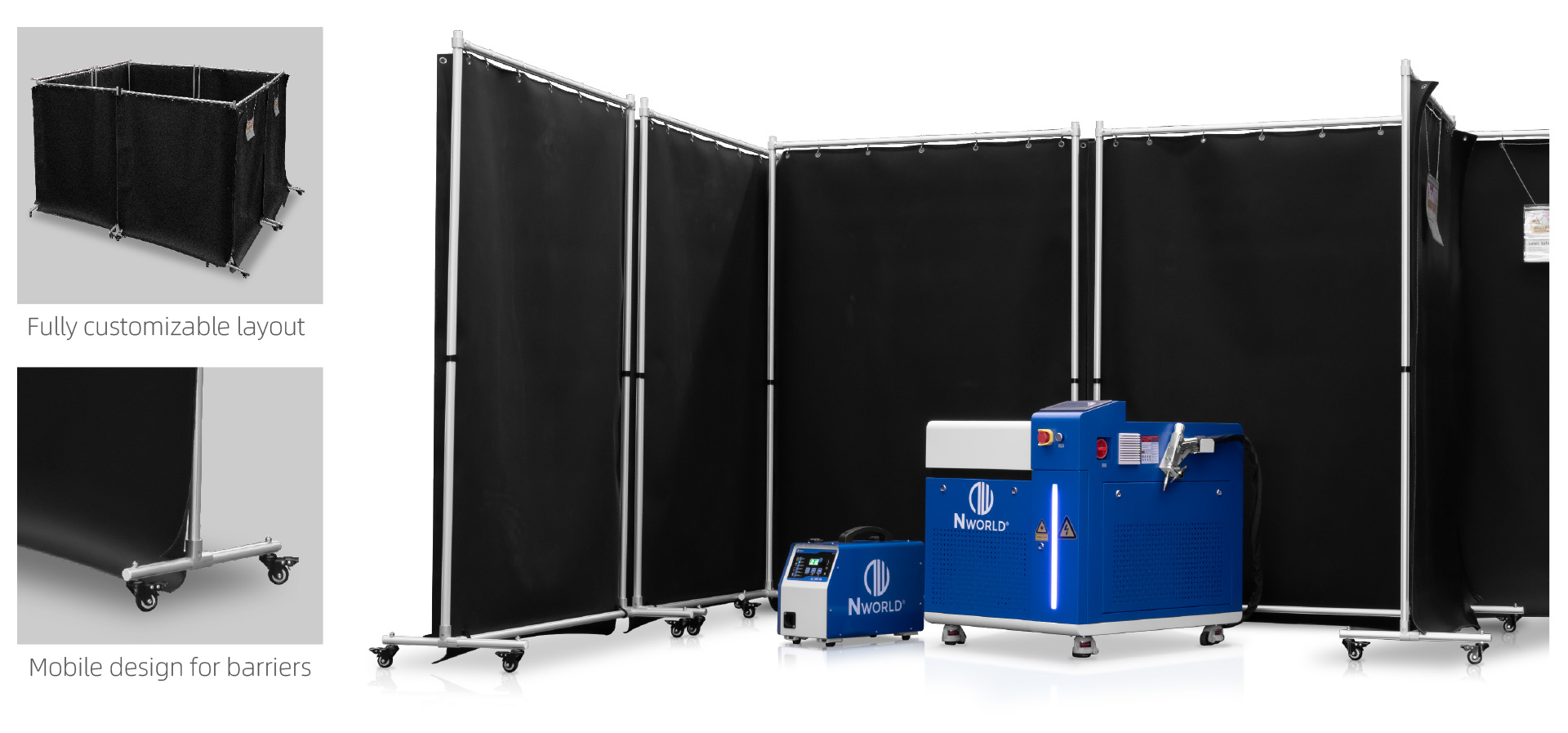

multiple safety protection

![]()

voltage variations resistant

![]()

Industry 4.0 ready

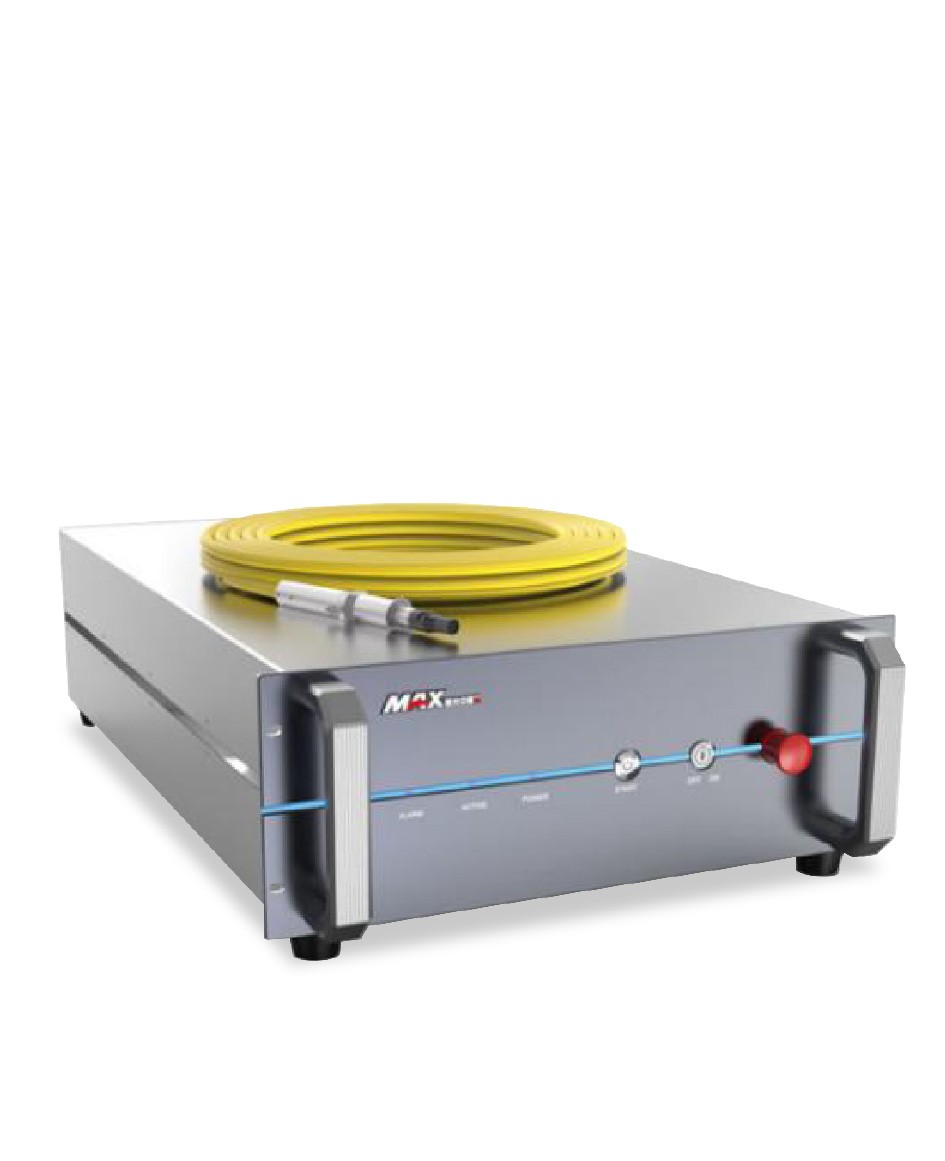

Components

High qualities components

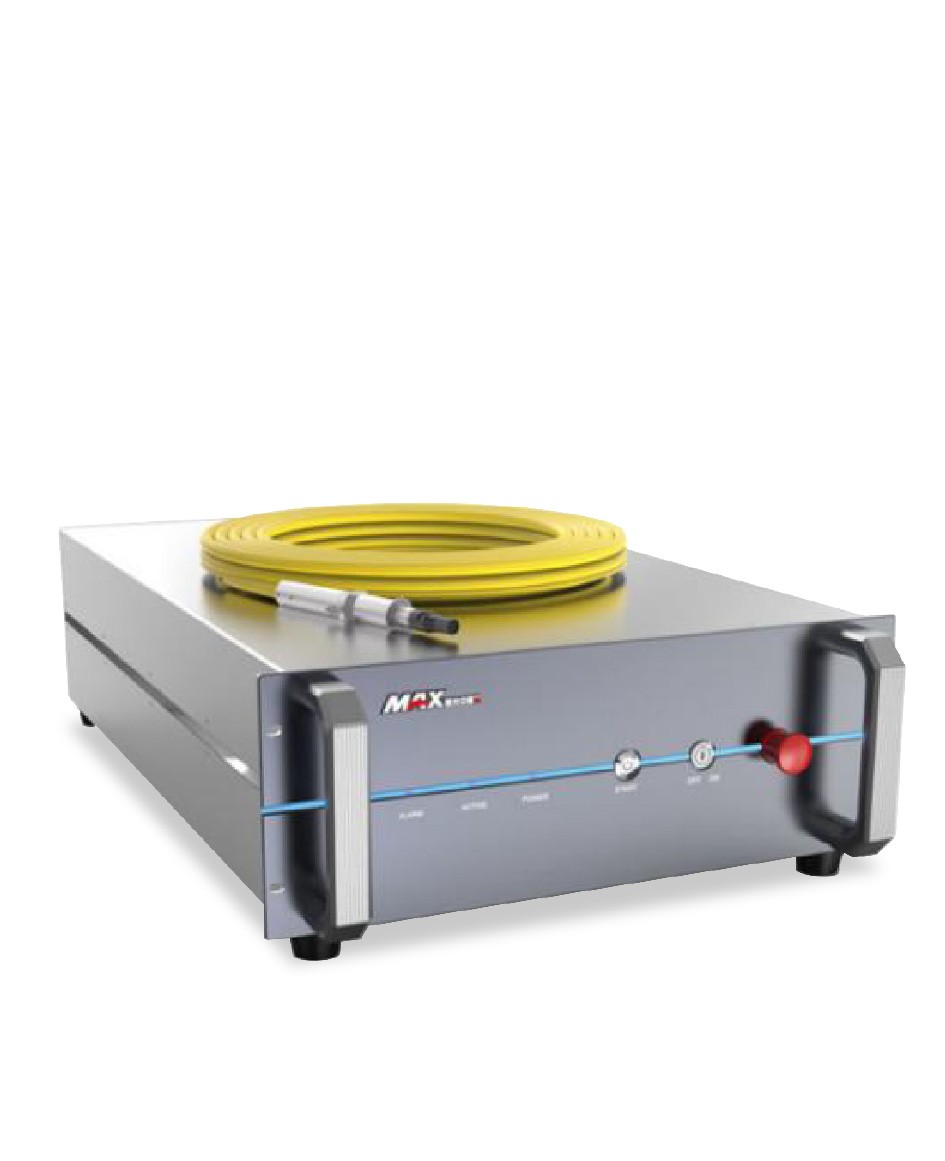

made by world well-known laser sources

MAX is currently largest manufacturer of fiber laser sources in the world. Now we chose the latest generation fiber source, protected against beam reflection. The latest model of the resonator achieves ultra-high power output, which translates into optimal performance and excellent weld quality. The photovoltaic conversion efficiency is more than 30%.

Hanli Industrial chiller

1. Professional matching laser welding machine, small size, compatible with cabinets of various manufacturers;

2. A full range of environmentally friendly refrigerant systems;

3. One-button intelligent control, convenient operation, ISO9001

quality management system, fault code query system;

4. Integrated design, convenient maintenance;

5. Stable and reliable performance, low failure rate, energy saving and power saving;

Auto-wobble Head

The wobble welding joint is independently developed, with wobble welding mode, adjustable spot width and strong welding fault tolerance, which makes up for the disadvantage of small laser welding spot, expands the tolerance range and weld width of machined parts, and obtains better weld line forming. The weight for the welding head is only 0.8 kg.

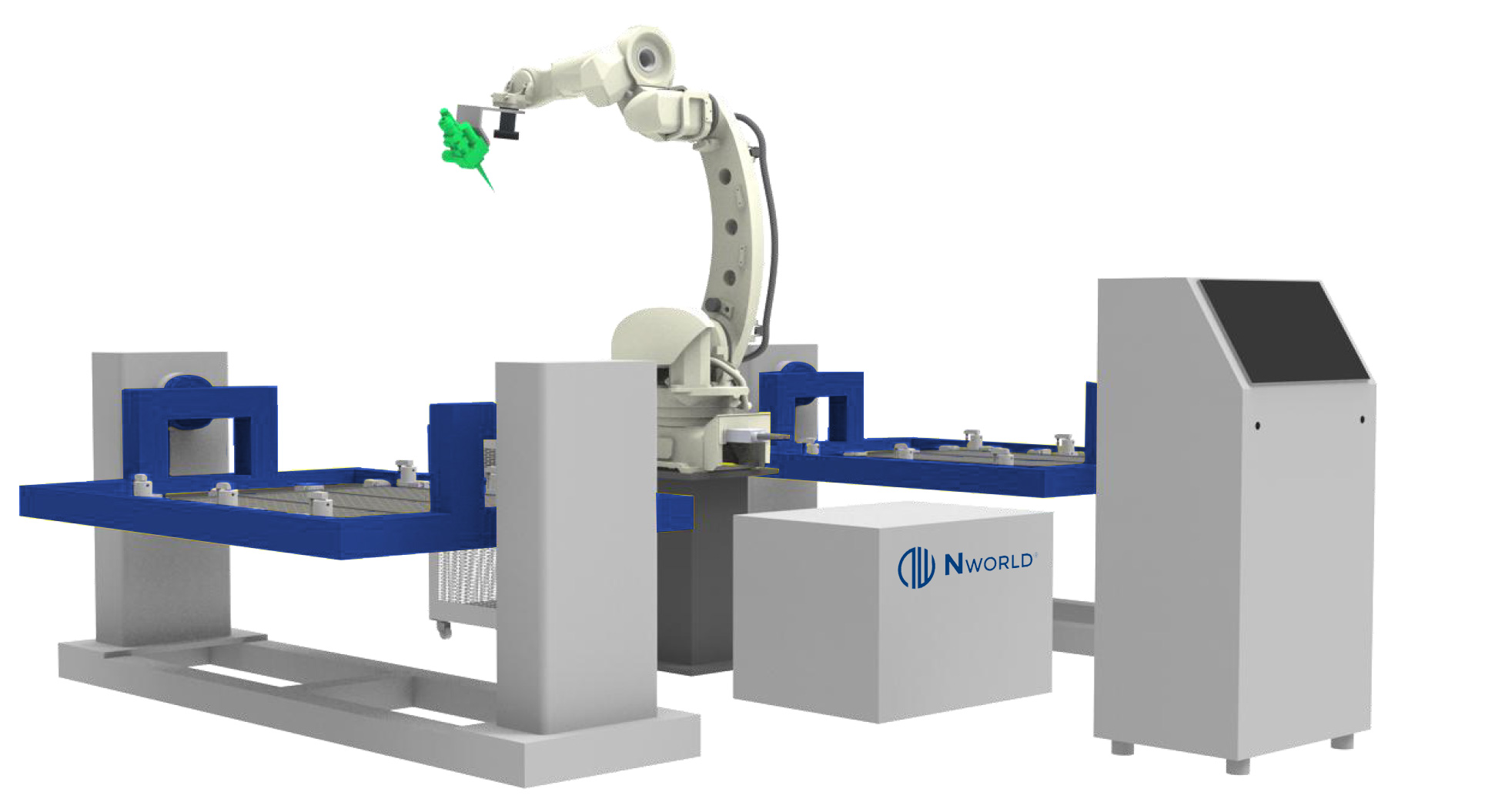

ROBOT LASER WELDING SYSTEM

ROBOT NW SERIES

new robot laser

welding system

The 3D Robot Laser Welding System is a comprehensive system platform for automated welding by industrial robots equipped with laser welders. It is mainly composed of three parts: robot system, laser welding system and auxiliary system

Six axes of linkage

High positioning accuracy

Multi-station collaborative work

Multiple safety protection

Compact structure and small footprint

High photoelectric conversion rate

Components

Robot System

1. Highly sensitive collision detection and flexible control.

2.Motion performance with high-speed and smooth motion.

3. Durable performance

4. Smaller control cabinet size, less equipment space.

5. Esier to control directly through the touch screen screen.

6. Suitable for new motion control, higher precision and faster speed.

Laser Welding System

MAX a first-class domestic brand, the new generation of Max lasers has higher photoelectric conversion efficiency (>30%), better and more stable beam quality, stronger anti-high-reflection ability, and at the same time introduces an optimized second-generation optical fiber transmission system to ensure more stable and precise welding effects. Advantages: 1. Maxphotonics laser source, big brand, more reliable.

2. The optical fiber core is thinner and the electro-optical conversion efficiency is higher.

3.High beam quality and strong system stability.

Auxiliary system

Each axis is driven by a maintenance-free AC servo motor. Each axis has automatic balancing and self-locking capabilities to ensure that the positioner does not lose control due to its own weight when the power is off or other unexpected stops. The workpiece can be clamped manually, and the positioning and clamping are fast and reliable. When the positioner rotates, it should be ensured that the workpiece does not loosen or slip. The clamping position should ensure that all welds are unobstructed to facilitate robot welding.

Functions and size can be customized as per real applications.